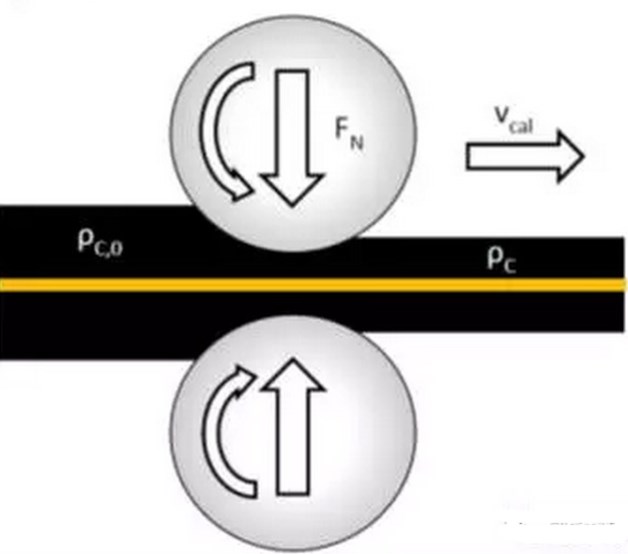

Coating refers to the process of evenly applying battery slurry onto the current collector to form a film. The electrode sheet is responsible for transferring charges to the electrolyte or receiving charges from the electrolyte in the battery. The coating thickness of the electrode sheet can have a significant impact on various performance indicators of the battery.

Firstly, the impact of electrode coating thickness on the battery's output voltage is quite pronounced. As the thickness of the coated film increases, the resistance between the electrode plate and the electrolyte also increases, leading to a reduction in the speed of electronic conduction and the efficiency of the electrode plate reaction. Conversely, if the film is too thin, the spacing between molecules decreases, increasing their interactions. This makes it difficult to adjust the energy levels of electrons, resulting in a reduction in the battery's output voltage. Therefore, during battery manufacturing, the coating film thickness must be adjusted based on different battery types and actual usage conditions to ensure optimal battery performance.

Secondly, changes in coating thickness directly affect the battery's capacity and lifespan. In general, battery capacity is inversely proportional to the thickness of the electrode coating. An excessively thick coating layer increases the internal resistance of the battery, thereby reducing its effective capacity. With prolonged usage, the battery's lifespan decreases. If the film is too thick, it leads to insufficient loading of the active electrode material, increasing the diffusion resistance of the electrode material during the cycling charge-discharge process, accelerating the decay of the battery's lifespan. Therefore, in production practice, appropriate coating thickness should be selected based on the battery's usage environment and performance requirements to achieve the best capacity and lifespan.

Additionally, variations in electrode coating thickness also affect the battery's charging rate and energy density. A too-thin coating layer may cause charge accumulation on the electrode plate, leading to localized overvoltage. On the other hand, a too-thick coating layer reduces the current density and power density of the battery during charge and discharge. Therefore, in battery manufacturing, a comprehensive consideration of factors such as battery structure, material properties, and usage environment is required to ensure that the electrode coating thickness meets the requirements for charge-discharge efficiency, charging rate, energy density, and other aspects.

In summary, the electrode coating thickness has a significant impact on battery performance. Choosing the appropriate coating thickness can enhance battery performance, reduce costs, and minimize resource waste. Therefore, researchers in relevant fields should strengthen their research on electrode coating technology, continuously optimize battery performance, and truly achieve the sustainable development of battery technology.