AGM batteries, known as Absorbent Glass Mat batteries, are a type of valve regulated lead acid (VRLA) battery.The main feature of AGM batteries is the use of a glass fiber mat as a separator, which is capable of absorbing and retaining the electrolyte while also isolating the positive and negative plates within the battery.

AGM (Absorbent Glass Mat) battery operates based on the same principles as a sealed lead-acid battery but with a different structural design. Here is a detailed explanation of the working principle of an AGM battery.

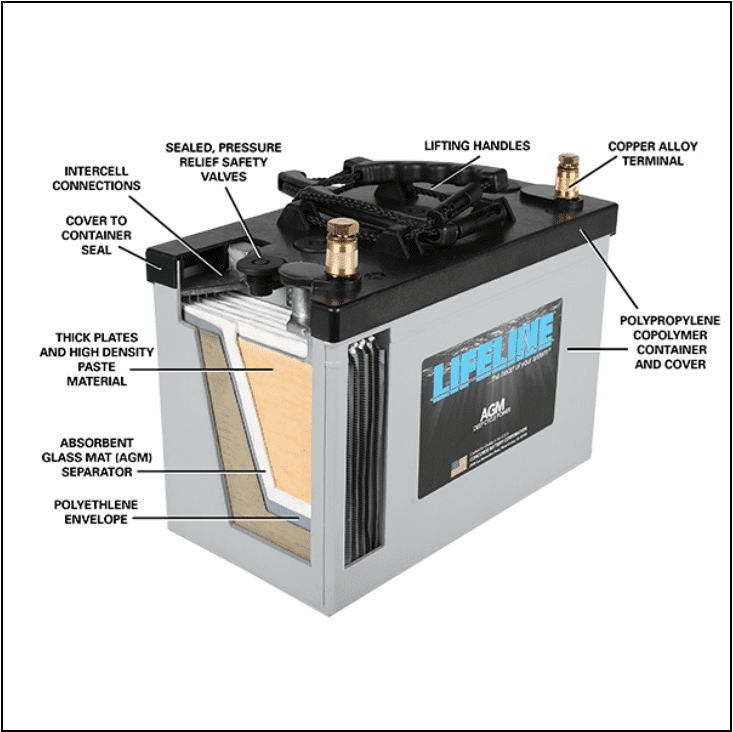

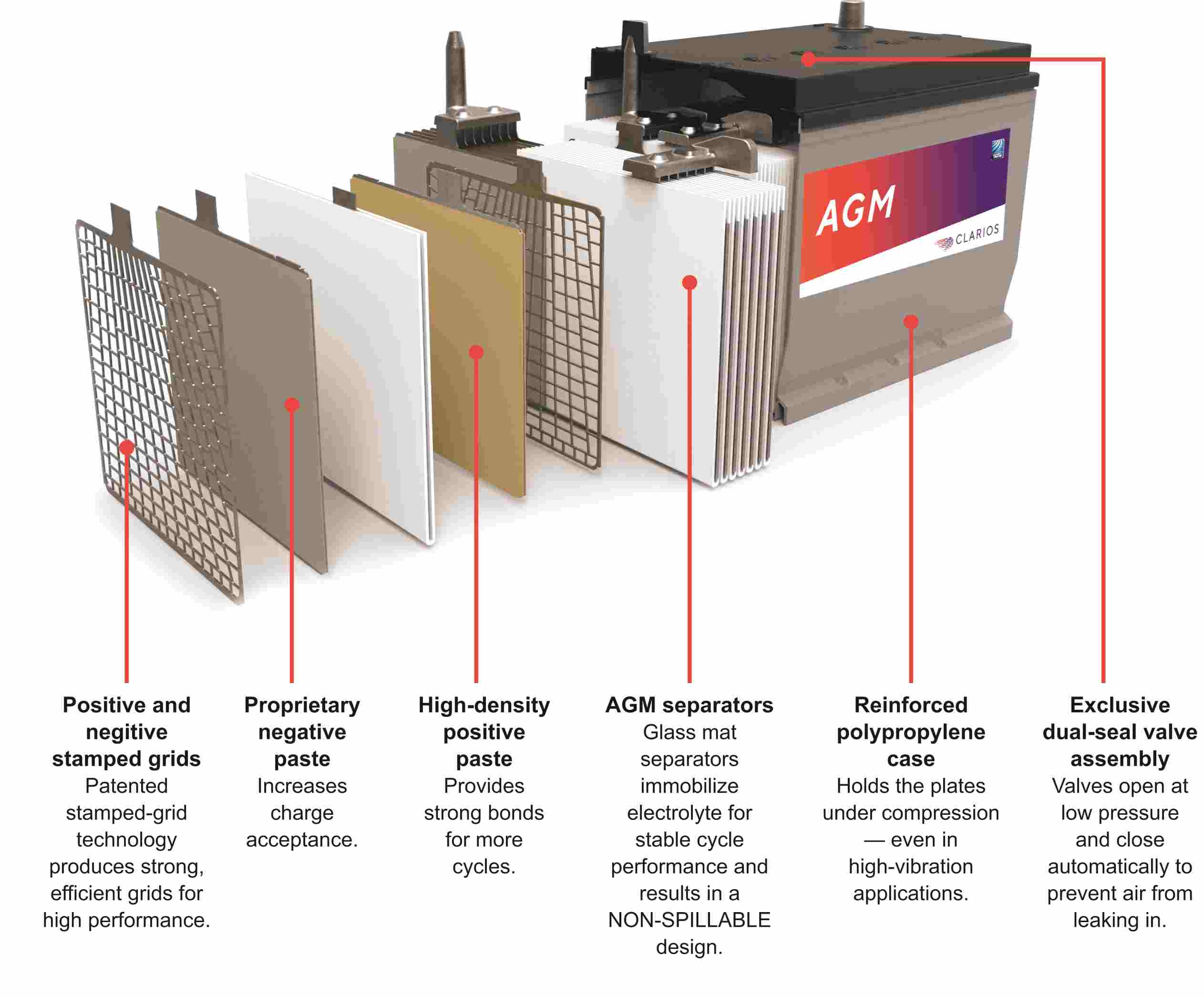

An AGM battery consists of positive plates (made of lead-calcium alloy), negative plates (made of pure lead), electrolyte (sulfuric acid), and an absorbent glass mat layer (AGM). The AGM layer is tightly packed between the positive and negative plates to maintain a stable distribution of the electrolyte.

The AGM layer is a critical component of the AGM battery. It is made of a fiberglass material that can absorb and retain the electrolyte. The fiber mat utilizes capillary action to immobilize the electrolyte within its structure, preventing free flow of the electrolyte.

AGM batteries use sulfuric acid as the electrolyte. The electrolyte is absorbed by the fiberglass mat, saturating it and maintaining it between the positive and negative plates. This construction allows the electrolyte to come into full contact with the electrodes, enabling the battery's chemical reactions.

During the charging process, lead-acid on the positive plate is chemically reduced to the positive active material, while lead acid on the negative plate is oxidized to the negative active material. This chemical reaction generates an electric current, with electrons moving from the negative to the positive terminal, charging the battery.

During discharge, the chemical reaction between the positive and negative active materials is reversed, producing an electric current that powers external loads. The sulfuric acid in the electrolyte serves as a conductor and facilitates the transfer of charges.

AGM batteries are sealed, preventing electrolyte leakage. This sealed structure enhances the safety of AGM batteries and allows them to be installed in various orientations.

Maintenance free operation:AGM batteries are designed with a high level of safety and convenience in mind, offering a spill proof and virtually maintenance-free operation.The key to their spill-proof nature lies in the absorbent glass mat (AGM) separator, which is impregnated with the electrolyte and effectively immobilizes it.This prevents the free movement of liquid that could lead to spillage, even in the event of the battery being tipped over or subjected to vigorous shaking.As a result, AGM batteries can be installed in various orientations, providing flexibility for use in different applications without the risk of leakage.The maintenance-free aspect of AGM batteries is also a significant advantage, particularly for users who require a reliable power source without the need for regular upkeep.Traditional lead-acid batteries often require periodic checks and refilling of water to maintain the electrolyte levels, which can be cumbersome and time consuming.In contrast, AGM batteries eliminate this need because the electrolyte is retained within the glass mat. This sealed design also contributes to a lower rate of self-discharge, meaning the battery can hold its charge for longer periods when not in use, further reducing the need for maintenance.

Deep cycling capability:Unlike traditional lead acid batteries, AGM batteries are constructed with a glass mat separator that is saturated with electrolyte, which provides a greater surface area for the electrochemical reactions.Furthermore, the AGM battery's ability to handle deep cycling is also linked to its low internal resistance, which means less energy is wasted as heat during the discharge process.The deep cycling capability of AGM batteries is further enhanced by their resistance to sulfation—a common problem in lead-acid batteries that can lead to reduced capacity and eventual failure.

Longer lifespan:AGM batteries are engineered to provide a longer lifespan compared to traditional lead-acid batteries, a feature that is highly valued in various applications.This extended lifespan is attributed to several factors inherent in the AGM design.Firstly, the AGM battery's construction, which includes a glass fiber mat that absorbs and holds the electrolyte, allows for a more controlled chemical reaction.This control minimizes the production of gas bubbles that can cause the active material to shed, a common issue in traditional batteries that leads to a reduction in overall lifespan.Secondly, AGM batteries are designed to have a lower rate of self-discharge, meaning they hold their charge for longer periods when not in use.Additionally, the robustness of the AGM battery's construction makes it more resistant to the effects of deep cycling and high temperatures, both of which can degrade the performance and lifespan of traditional batteries.The AGM battery's ability to endure deep discharges without significant damage to its internal components is a testament to its resilience and is a key reason why AGM batteries are often specified for use in demanding applications like renewable energy storage systems and electric vehicles.

High energy density and fast charging:AGM batteries are recognized for their high energy density and rapid charging capabilities, which are integral to their performance superiority over traditional lead-acid batteries.The energy density of a battery is a measure of the amount of energy stored per unit of weight, and AGM batteries excel in this regard due to their efficient design. The AGM separator's glass mat structure, enriched with electrolyte, allows for a larger surface area for the electrochemical reactions to occur, which in turn enables the battery to store more energy within the same physical space.This high energy density translates to longer runtimes and greater reliability for applications requiring substantial power.When it comes to charging, the AGM battery's design also shines.The glass mat separator facilitates faster ion exchange, which accelerates the charging process.This means AGM batteries can be charged to their full capacity much more quickly than traditional batteries, often in half the time or even less.

Vibration and shock resistance: AGM batteries are renowned for their exceptional resistance to vibration and shock, a critical feature that sets them apart from traditional lead-acid batteries. This resilience stems from the AGM battery's construction, where the electrolyte is absorbed within a special glass mat separator, rather than freely moving within the battery as in flooded batteries. The immobilization of the electrolyte within the glass mat minimizes the movement of the electrolyte and reduces the risk of damage from mechanical stress. This design ensures that the battery can withstand the rigors of high-vibration environments, such as those encountered in off-road vehicles, marine applications, and heavy machinery. Additionally, the compact and robust nature of the AGM battery construction contributes to its ability to tolerate shock without significant degradation in performance. This vibration and shock resistance not only prolongs the operational life of the battery but also makes AGM batteries an ideal choice for applications where mechanical stability is paramount, such as in military, aerospace, and certain industrial settings.

Low internal resistance:AGM batteries are distinguished by their lower internal resistance when compared to conventional lead acid batteries, a feature that significantly impacts their performance capabilities. The key to this advantage lies in the AGM's construction, which incorporates a special glass fiber mat, or separator, that is saturated with an electrolyte solution. This mat is positioned between the lead plates, creating a structure that allows for a more efficient and faster ionic exchange during the electrochemical reactions that occur within the battery. The close proximity of the electrolyte to the active materials in the plates minimizes the distance that ions must travel, thereby reducing the energy lost as heat and enabling AGM batteries to deliver power more efficiently. This lower internal resistance not only facilitates quicker recharge times but also supports higher discharge rates, making AGM batteries particularly suitable for applications that demand rapid bursts of power, such as engine starts in cold conditions or high-drain electronic devices. Furthermore, the reduced internal resistance contributes to the battery's ability to perform well over a longer period, which is one of the reasons AGM batteries are favored for deep-cycle applications and are often specified for use in modern, technology-laden vehicles.

Higher cost:AGM batteries are more expensive compared to traditional lead-acid batteries primarily due to their advanced design and manufacturing processes. The use of specialized materials, such as the absorbed glass mat separators and high-quality electrolytes, adds to the production cost.

Susceptibility to overcharging:AGM batteries are more susceptible to damage when subjected to excessive charging currents or voltages. Overcharging can lead to a rapid degradation of the battery's components, reducing its overall lifespan and potentially causing it to fail prematurely.

AGM batteries are prized for their versatile applications and high performance, offering distinct advantages across a wide range of uses.They are a popular choice in the automotive industry for their ability to manage high electrical loads and provide reliable cold starts.In marine applications, their resistance to vibration and capacity to operate in various positions make them ideal for powering boats' essential systems.AGM batteries also excel in recreational vehicles, ensuring consistent power supply despite frequent use and environmental fluctuations.As a storage solution for solar and wind energy, they provide deep cycling capabilities and longevity, effectively managing energy collected for later use.In uninterruptible power supply (UPS) systems, they offer the swift response and dependability required to protect against power outages.Their performance characteristics make them suitable for motive power in electric forklifts and other material handling equipment.Furthermore, AGM batteries are favored in military and aerospace applications for their ability to operate under extreme conditions with high reliability and safety.In healthcare, they serve as a backup for critical medical devices, ensuring operational continuity during power failures.They are also utilized in telecommunications for maintaining communication infrastructure.For those living off-grid or in need of emergency power, AGM batteries are a dependable choice, offering deep cycling and rapid recharging. Overall, the value of AGM batteries is encapsulated in their reliability, safety, and low-maintenance nature, which translates into extended service life and peace of mind in various demanding applications.

NEWARE TECHNOLOGY LLC

755 Ames Avenue, Milpitas, CA, USA, 95035