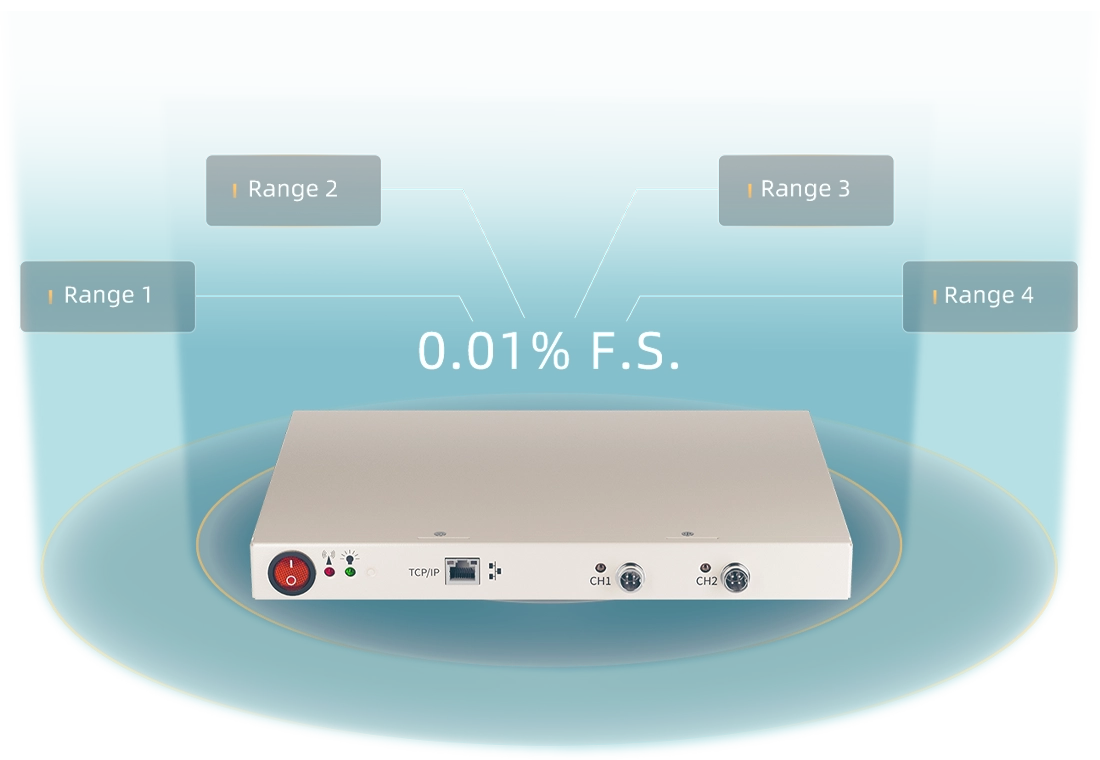

4 current ranges from 0.5μA ~ 0.1mA, 0.1mA ~ 1mA, 1mA ~ 10mA , 10mA ~100mA can be selected to realize the controllable accuracy of small current in small range.

● Discharge Data Protection

● Offline Testing Function

● Voltage Upper Limit Setting

● Voltage Lower Limit Setting

● Current Upper Limit Setting

● Current Lower Limit Setting

● Capacity Upper Limit Setting

● Delay Time Setting

Delicate measurements at μA-level current, uncovering the essence of testing.

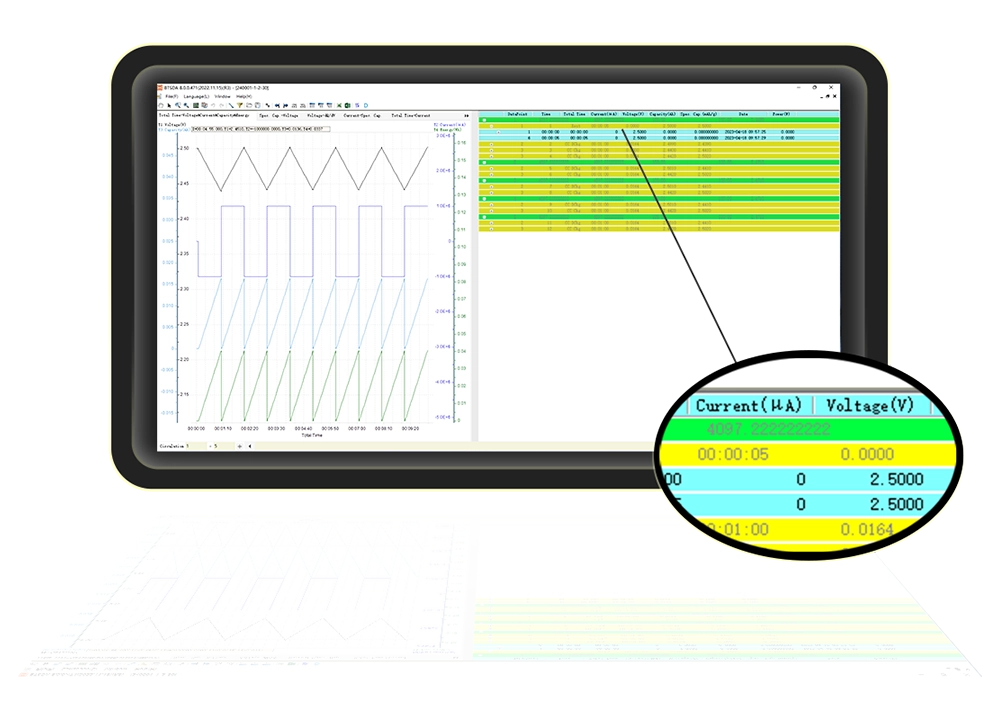

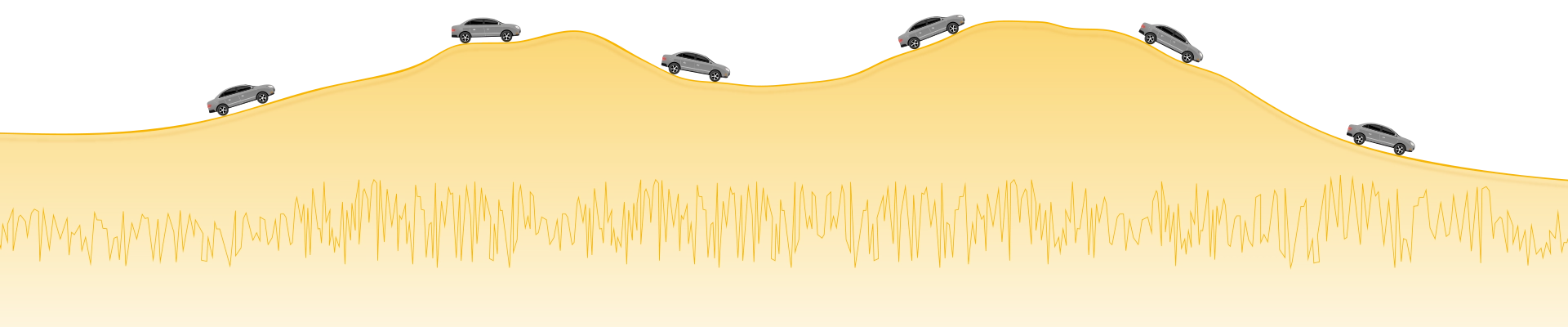

Based on NEWARE 5th generation test system architecture, it can perform Cycle Life Test, Rate Charging / Discharging Test, Pulse Simulation Test, HPPC, etc. Meanwhile, it can simulate the actual driving road conditions of electric vehicles by dynamic power or current waveform.

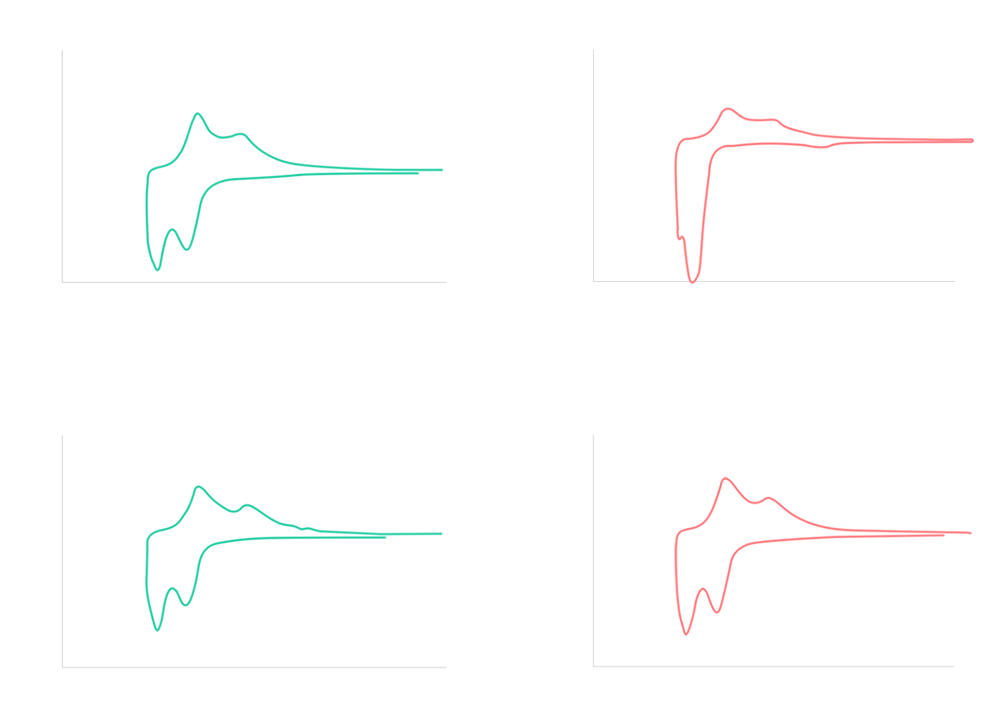

Tailored for advanced battery testing: enabling dQ/dV differential capacity curve analysis capability.

The software is fully functional, covering a variety of work-step settings, recording, and data storage to meet a wide range of testing needs.

Integrated peripheral devices such as Auxiliary Voltage, Auxiliary Temperature, and Environmental TestChambers for comprehensive testing and evaluation, providing multi-dimensional and quantifiable support for battery mass production testing.