In the fiercely competitive automotive market, with price wars playing out relentlessly, prominent automotive giants like BYD and Tesla, with their deep profit pools, often engage in fierce battles, setting the stage for the foreseeable competitive landscape in the Chinese automotive market over the next few years.

In these harsh survival conditions, the only way to withstand the industry storm is by controlling the entire technological chain, delivering on the ground, and achieving outstanding product capabilities.

"A technology can only demonstrate its value when it is truly used in a car and proves to be functional and user-friendly," said the chairman of Leap Motor, Zhu Jiangming, during the company's self-developed open day on January 10, 2024, sparking industry resonance. On that day, Leap Motor unveiled the core technologies of the LEAP 3.0, comprising six major modules.

Amid the industry's dazzling technological concepts and the current sluggish implementation, Leap Motor's insistence and call for "technology on the car" seem more like a declaration of war. As a newly established car company selling over ten thousand vehicles annually, how can Leap Motor boldly claim that "value has a reference"?

Becoming a reference in the industry implies becoming a benchmark for similar products in the industry. This greatly tests a team's hard work in product definition and cost control, and when reflected in the company's backend capabilities, it signifies mastery of core technologies – precisely the soul of Leap Motor.

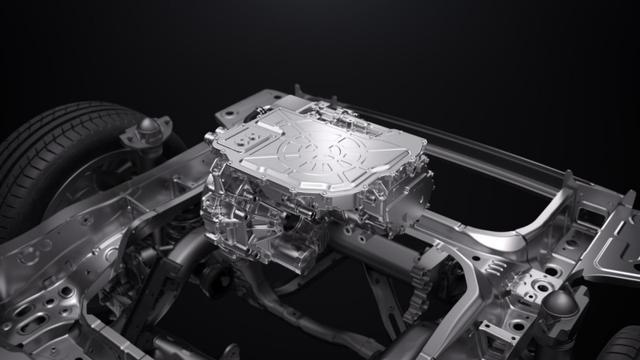

During the open day, Leap Motor introduced the core technologies of the LEAP 3.0, including the four-leaf clover central integrated electronic and electrical architecture, three-electric technology, intelligent cockpit enhanced by the 8295, smart driving, and globalized vehicle architecture, among other technical modules.

Zhu Jiangming, Chairman of Leap Motor, confidently stated, "For users, a technology can only truly demonstrate its value when it is implemented in a car and proves to be functional and user-friendly. The core technologies of the LEAP 3.0, released by Leap Motor, are already in mass production and readily available, with no futures contracts."

Since the wave of new car manufacturing began in 2014, sweeping through the industry for over a decade, many companies have silently appeared and disappeared during this period. Some once dominant companies, like WM Motor and Byton, eventually faded into obscurity.

Even among the car companies still in the game today, only a few have maintained robust momentum and a stable foundation. Leap Motor happens to be one of them.

In 2023, with flagship products like C11 and C01, Leap Motor achieved a total sales volume of 144,155 units, a 29% year-on-year increase, securing its position as the third-largest new car manufacturer. The driving force behind this success is the product strength and cost-effectiveness supported by Leap Motor's comprehensive technological layout.

As of today, Leap Motor's self-developed technological system has clearly entered the 3.0 era, with a dual focus on electric and intelligent advancements, preparing to face even more intense competition in the automotive market in the next two years.

The two core components of smart electric vehicles—battery performance upgrades exceeding 10% annually and the evolution of computing power following Moore's Law—indicate the fast-paced nature of the smart electric vehicle industry. To maintain a leading position in the industry, any top-tier car manufacturer must intensify its technological research and development. Otherwise, in the rapidly evolving industry landscape, they will merely become followers and spectators, struggling to gain an advantage.

Byd's 20 years of perseverance and dedication to the electric vehicle industry paid off when they seized the opportunity, achieving price parity between electric and traditional vehicles. This move allowed them to reap the maximum benefits of new energy vehicles, with sales almost doubling from 2022 to 2023, enabling the company to break free from financial struggles and achieve a daily profit of one billion yuan.

Similarly, Huawei, entering the market in less than three years, has approached 30,000 monthly sales with its best-selling model, the M7. After the release of the M9, it garnered a substantial number of orders. Behind this success lies Huawei's accumulated experience of 30 years in the ICT field and over a decade of technological groundwork in the automotive sector.

As a pioneer in smart electric vehicles, Tesla's technological depth is beyond compare, covering extensive research and development from batteries, motors, chips, and seats to body manufacturing.

Recognizing this, Zhu Jiangming, with an IT background, established Leap Motor in 2015 and set out to create a comprehensive self-developed technological roadmap for the company.

What does comprehensive self-development mean for Leap Motor? The company interprets it as starting from the ground up to build the most critical aspects of the car, such as power, intelligent driving, cockpit, electronic and electrical systems, achieving "software + hardware" independent development. Leveraging this comprehensive self-development, Leap Motor deeply integrates electronic components, enabling rapid adaptation to the new demands of the software-defined car era.

In the core area of the three electric fields in electric vehicles, Leap Motor not only self-develops but also produces a considerable amount in-house, even manufacturing the battery pack casing. This level of control enables Leap Motor to firmly manage the most critical cost component of electric vehicles—the battery.

Traditionally, batteries often constituted around 40% of the total vehicle cost, contributing to the high selling prices of electric vehicles. Engaging in lengthy negotiations with battery manufacturers has been a thorn in the side for many automakers. For instance, the chairman of GAC Motor once humorously claimed to be working for the battery factory.

However, Leap Motor chose a different path, opting to comprehensively self-develop and produce from the battery pack to the module, significantly helping the company save costs.

Leap Motor has achieved almost unique capabilities in the industry by standardizing battery purchases, allowing monthly negotiations with battery suppliers to gain cost negotiation power. Additionally, with full self-development, the cost of the parts outside the battery cells in the battery pack has fallen below 0.1 yuan per watt-hour. If we calculate this based on the 70 kWh of the C10, Leap Motor's battery pack's total cost is now less than 35,000 yuan, nearly slipping to 20% of the total vehicle cost. This is evidently an astonishing level of cost control.

During the technology open day, Leap Motor launched its first global model, the C10, with a pre-sale price range of 151,800 to 181,800 yuan for the extended-range version and a pre-sale price range of 155,800 to 185,800 yuan for the pure electric version.

Leap Motor has possessed this level of cost control ability for over a year, and currently, there are not many automakers in the industry that can achieve this.

The core reason is that many car manufacturers lack the in-depth self-research and self-production capabilities for battery packs, relying on external procurement of battery modules and packs. In such cases, changing a supplier requires at least one round of winter and summer whole-vehicle testing, taking a considerable amount of time, often over a year or even longer. How can monthly price negotiations with suppliers be feasible under such circumstances?

Cost control is the foundation of enterprises in the future high-intensity competition in the industry. It can be said that the ability to control costs determines whether an enterprise can survive and is the life and death, victory, and defeat of an enterprise.

Because only by effectively controlling costs can an enterprise confidently adopt a "cost pricing" approach, maximize configurations, and enhance its product competitiveness. Leap Motor has evidently laid a solid foundation in this regard. Moreover, beyond this, another core advantage of self-developed technology is controlling the delivery pace, ensuring timely implementation of technology.

In the traditional battery technology, the excessive expansion of batteries led to accelerated capacity decay. Leap Motor's CTC2.0 battery is non-modular, featuring an innovative zero-pressure technology that alleviates battery expansion, increasing battery mileage lifespan by 10%. Additionally, Leap Motor designed six safety control technologies (cell safety selection, thermal runaway warning, heat source isolation, puncture protection, directional pressure relief, intelligent cooling) to effectively suppress internal heat diffusion in case of cell failure, achieving 720 minutes of no heat diffusion, far exceeding the industry standard requirement of 5 minutes.

Moreover, CTC2.0 adopts a pragmatic design with a 250A charging capacity, covering 90% of the charging piles on the market, saving costs while ensuring replenishment efficiency. Of course, CTC2.0 also has the ability to expand to 800V, achieving 30% to 80% ultra-fast charging

in just 15 minutes. Furthermore, considering post-sales economics, Leap Motor's CTC2.0 structure's maintenance method is the same as the original independent battery pack and can be completely removed.

In terms of electric drive, this is Leap Motor's specialty. In its eight years of existence, Leap Motor has independently developed the core components of electric drive, realizing three generations of technological evolution. The team has experience in developing and producing multi-in-one and three-in-one, water-cooled and oil-cooled, and range extender systems, accumulating 383 patents on electric drive (191 of which are invention patents).

Specifically, the all-new intelligent oil-cooled electric drive platform under LEAP 3.0 has intelligent shunt cooling technology, with a 360° surround oil-cooling for the motor, resulting in more uniform cooling of the stator rotor and a 20% reduction in overall temperature gradient. It can provide a continuous maximum power exceeding 80 kW for the entire vehicle, ranking first in the same category's power system. The acceleration performance from zero to one hundred is not attenuated, with the number exceeding ten times that of water-cooled electric drives.

Additionally, Leap Motor's oil-cooled electric drive has a design life of over 600,000 kilometers, far exceeding the same level of new energy vehicle electric drives at home and abroad. According to reports, after a reliability verification of 600,000 kilometers, the power output remains as stable as ever, with an efficiency decrease of less than 0.5%, far better than the industry standard's recommended attenuation of no more than 5%.

Leap Motor has also gained global support through its technological advancements. In October of last year, the world's fourth-largest automaker, Stellantis, announced plans to invest approximately 1.5 billion euros to acquire about 20% of Leap Motor. Currently, Stellantis Group and Leap Motor have established the joint venture company "Leap International" with a 51% to 49% ownership structure, and this company exclusively holds the rights to manufacture Leap Motor products locally. It is reported that Stellantis' commercial buses appear weekly at Leap Motor's headquarters, rapidly advancing collaboration, including export and sales operations.

With an industry war looming and uncertainty shrouding every player, the answer to navigating through the storm might not be unique, but Leap Motor has clearly found what they excel at and has made a solid demonstration of it.