Mainly used for battery material research, material testing, and can also be used for small-scale trial production in schools, research institutes, and corporate laboratories.

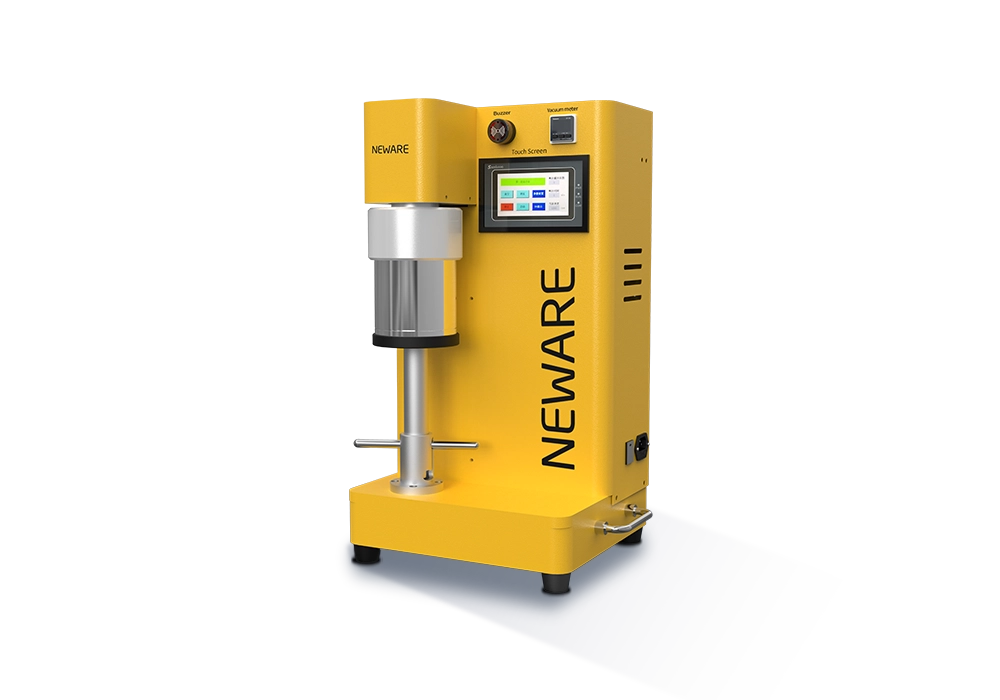

Vacuum Mixing:

Uniformly mix the slurry while maintaining a vacuum environment to prevent material oxidation.

Electrode Coating:

Evenly coat the slurry onto the current collector.

Electrode Rolling:

Apply pressure to roll the electrode.

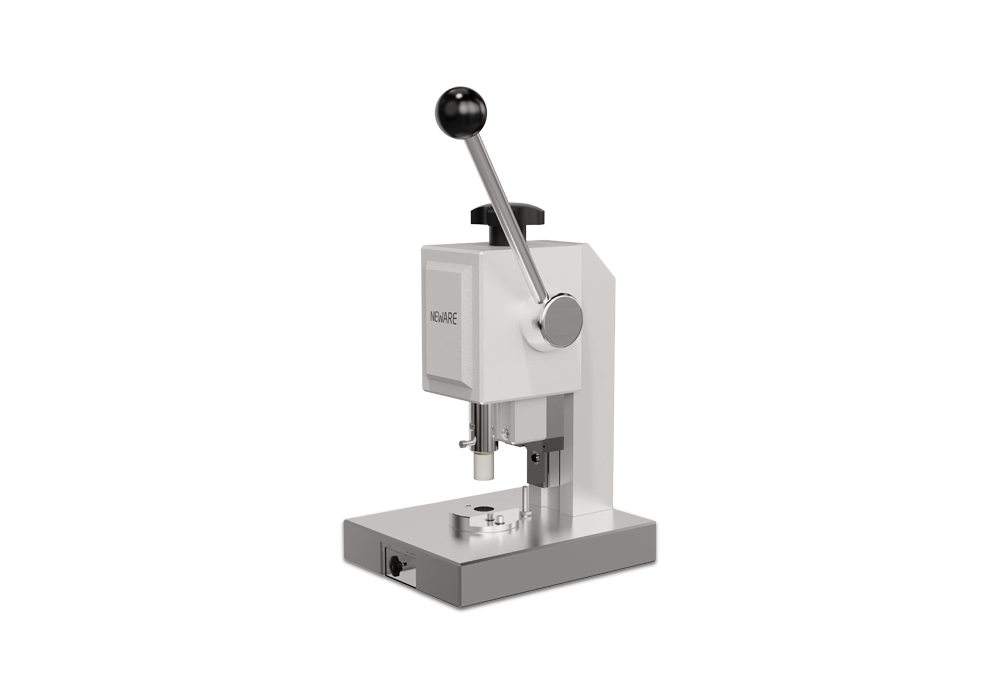

Electrode Punching:

Punch the electrode into desired shapes.

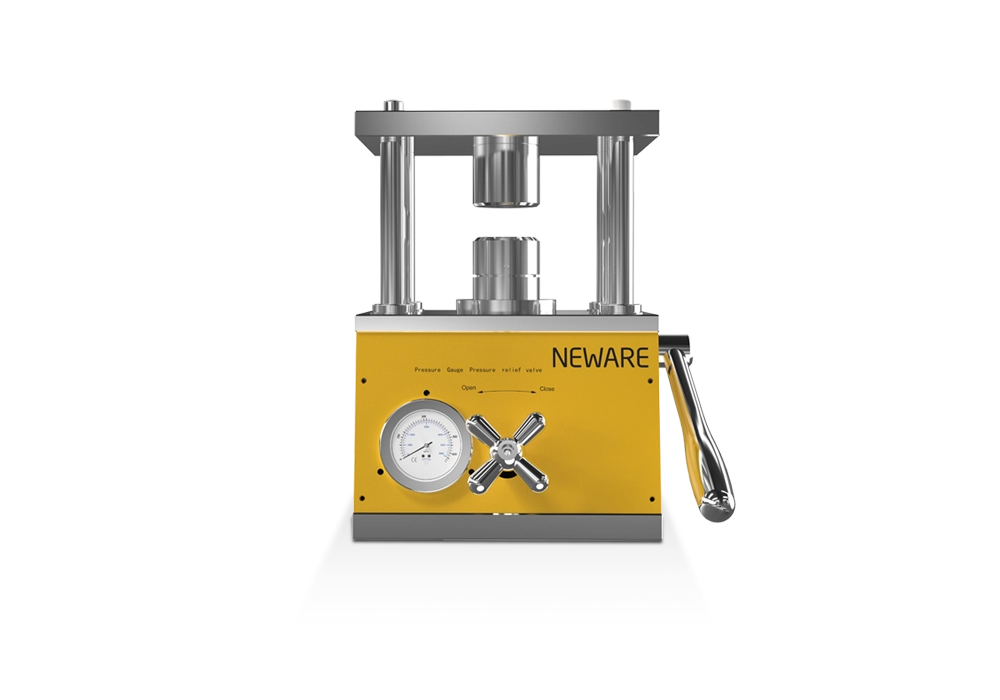

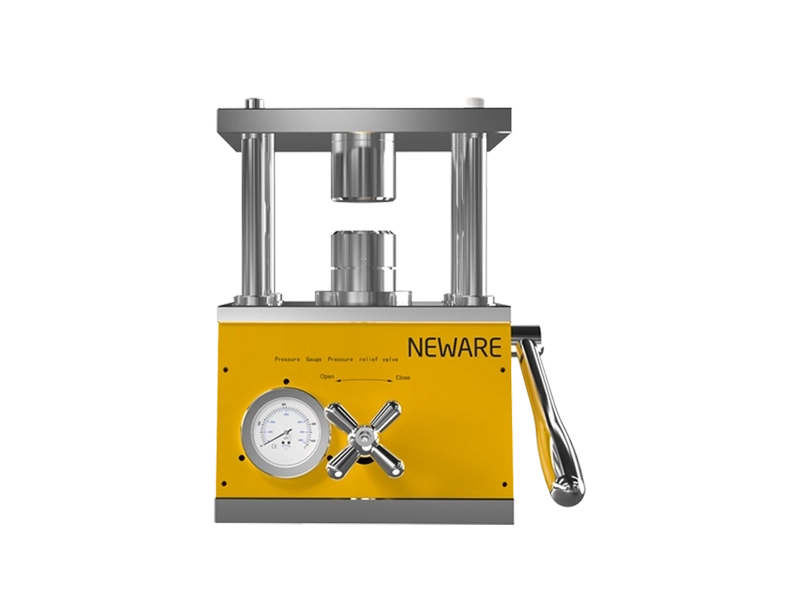

Battery Sealing:

Seal coin cells.

Built-in vacuum system, ensuring a vacuum environment during mixing, effectively eliminating bubbles generated during the stirring process. The mixer features a bracket design for easy operation and ensures operational safety during the vacuum mixing process.

*The standard configuration includes a 500ml stirring tank, and a 1L stirring tank can be customized.

The blender is controlled by a touch screen and supports multi-speed operation. It comes with a standard dual-axis screw-type stirring paddle, and an optional single-axis blade-type stirring paddle can also be selected. Different stirring shaft forms and combinations are available according to the size of the mixing tank, enabling rapid and uniform mixing and dispersion of materials in all directions.

Automatic coating machine with built-in vacuum pump, providing precise coating. The machine allows for quick placement or removal of current collector. When the vacuum is activated, the substrate adheres to the vacuum plate without any deformation, ensuring accurate coating.

An optional automatic coating drying machine is available, featuring a large heating area on the top and multiple circulating fans to ensure high-precision temperature uniformity within the chamber, enabling fast drying.

The surface is treated with hard chrome plating, providing resistance to oxidation and rust. It is equipped with a guide plate for easy feeding and rolling of sheet materials. It supports forward or reverse rotation, allowing for convenient material retraction when issues are encountered during operation.

The machine is driven by an electric motor and features gear transmission to achieve roller pressing. The gap between the pressure plates can be adjusted by rotating the adjustment handwheel in both clockwise and counterclockwise directions.

By shaking the hand lever, the upper punch moves downward and punches into the lower template, cutting the material. Once completed, the punched material can be taken out from the collecting box.The upper punch module adopts high-precision slide rail guidance, resulting in a smoother cut with no burrs, rough edges, or indentation marks.

Optional die sizes range from 0.12" to 0.94" (3~24mm), suitable for punching and cutting films on battery positive and negative electrodes, separators, and other materials with thicknesses ≤0.02"(0.5mm). Customized molds can also be made according to specific requirements.

The coin cell sealing machine adopts hydraulic drive, ensuring vibration-free and leak-free sealing of the battery. It operates purely manually, with an ergonomically designed handle for effortless operation.

The standard molds provided are suitable for the packaging process of 20-series coin cells. After mold replacement, the machine can be used for sealing other sizes of coin battery cells. Additionally, there is an option to select a shell removal mold for the disassembly process of coin cells.