NEWARE WIHW-200-160CH-B button battery all in one battery tester, combines charging and discharging tests with constant temperature testing capabilities. It is a comprehensive system that integrates a temperature chamber, charge-discharge equipment, and a central control unit. The temperature chamber function allows for the maintenance of a stable temperature environment within a certain range, simulating the performance of batteries under different operating conditions.By conducting experiments such as charge-discharge cycles, cycle life testing, and safety assessments within the constant temperature test chamber, the system can evaluate the performance, stability, and safety of batteries. It provides crucial data support for battery research, production, and quality control.

The Button Battery All-in-One Battery Tester is primarily used for temperature performance testing of button batteries, especially for lithium-ion batteries and polymer lithium-ion batteries. In summary, the Button Battery All-in-One Tester enables efficient and precise testing and research of temperature performance for button batteries, meeting the diverse testing needs of material manufacturers, universities, and research institutions.

Temperature Control: The tester is equipped with temperature sensors and a control system inside the test chamber, allowing real-time monitoring and adjustment of the internal temperature. By controlling heating or cooling devices, the test chamber can maintain a set constant temperature.

Constant Temperature Environment: When a target temperature is set, the test chamber adjusts based on real-time temperature data to ensure the internal temperature remains stable at the set value, providing a constant temperature environment for battery testing.

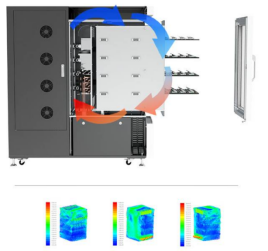

Ventilation and Exhaust: The test chamber maintains air circulation to prevent temperature unevenness. Typically, a ventilation system is set up during the testing process to ensure air circulation and uniform temperature distribution.

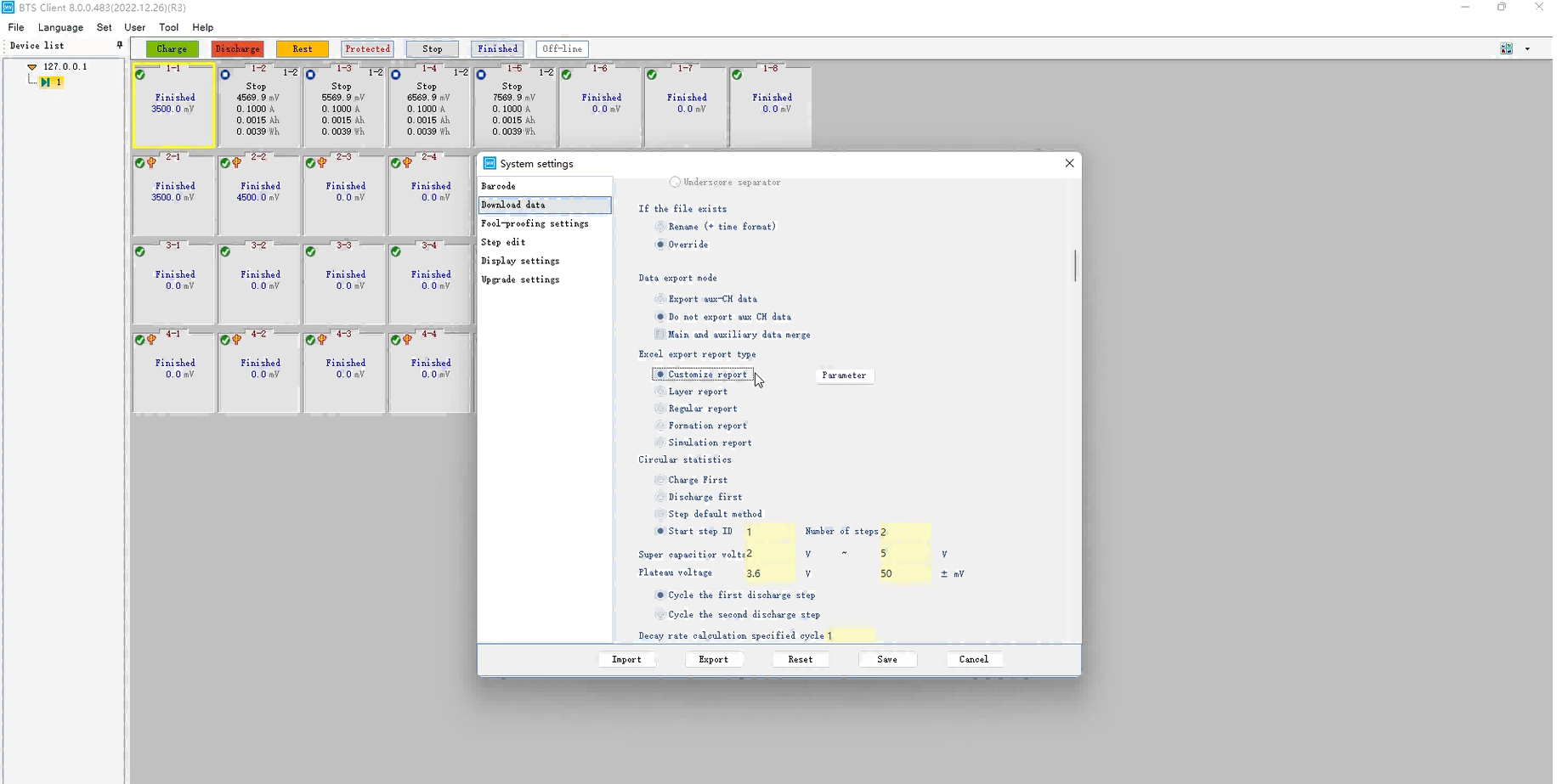

Data Acquisition and Logging: The test chamber can be connected to BTS software for data logging. It can record the performance parameters of batteries at different temperatures, such as voltage, current, and temperature. This data supports subsequent analysis and evaluation.

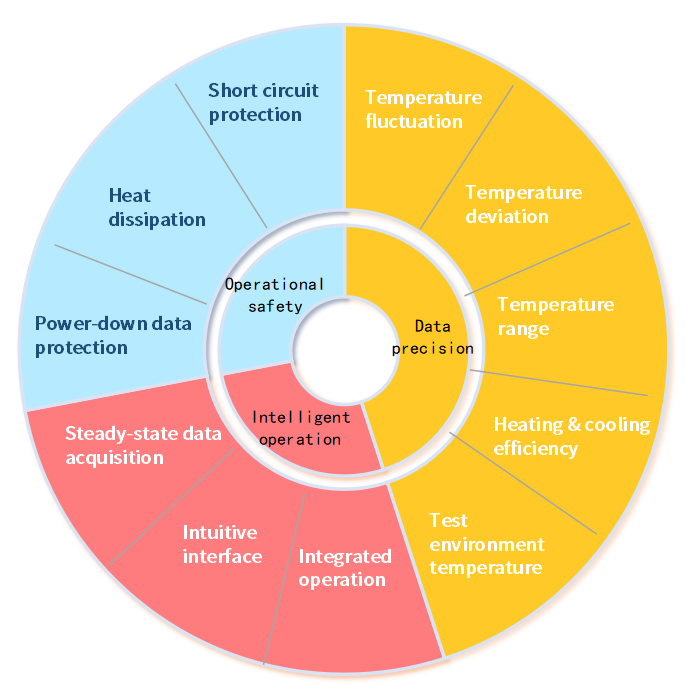

There are several key factors to consider when purchasing a Button Battery All-in-One Battery Tester, as outlined in the diagram below. These factors can be broadly categorized into three key points: testing accuracy, operational intelligence, and experimental safety.

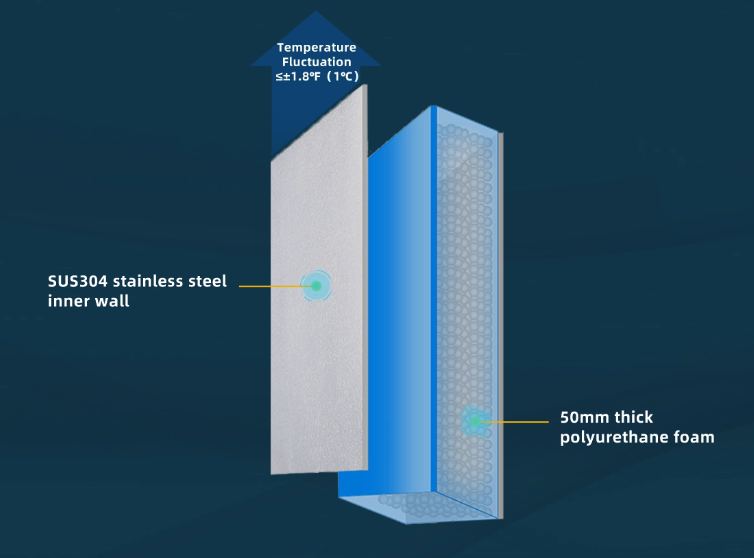

-Temperature fluctuation ≤ 1°C (under no-load and stable temperature conditions)

-Temperature deviation ±2.0°C (under no-load and stable temperature conditions)

-Heating time ≤ 30 minutes (25°C to 60°C)

-Cooling time ≤ 50 minutes (25°C to 0°C)

-Temperature range: 0°C to 60°C

-Test environment temperature: 0°C to 30°C

-Cyclic air circulation ensures uniform airflow with no dead zones, maintaining a constant temperature over a long period of time.

-Dedicated four-channel cable. The charging and discharging equipment is connected to the back of the temperature chamber, using a single channel cable for all four channels. Each individual unit only needs to connect two cables, reducing the number of channel cables and effectively minimizing temperature fluctuations.

-SUS304 stainless steel plate combined with a 50mm thick polyurethane foam insulation provides effective thermal insulation, reducing energy loss, and offering superior internal constant temperature protection. This ensures more precise and reliable test results.

-Independently developed temperature control components undergo reliability performance testing such as high and low-temperature shock and vibration, as well as EMC testing. These components can monitor temperature variations in the equipment and adjust heating or cooling devices through feedback control systems to maintain a stable temperature.

-The communication conversion module and Ethernet interface enable data communication and connectivity between the equipment and the network. It allows the BTS software to intelligently control the equipment, set and execute various tasks, achieve real-time data transmission, and perform real-time analysis of core data. The BTS interface is user-friendly, easy for novice users to understand and operate, and the software version is stable.BTS software tutorials are available on site

Offline Storage: The central unit of the tester has 1GB of built-in memory, allowing it to automatically save multiple independent charging logs without the need for computer monitoring. This ensures data protection even in the event of unexpected power outages. Users can also view, analyze, and delete historical discharge data. Through the USB interface, users can copy and transfer data from the discharge process to a computer. By utilizing the BTSDA data processing software, users can conduct in-depth analysis of battery discharge processes and create corresponding data reports, making data storage and transfer more convenient.

Export Support: The software can simultaneously display voltage, current curve data, and more, and it allows exporting data in formats such as TXT, Excel, PDF, CSV, and others.

Real-time Curves: The software provides real-time curves that allow users to promptly identify any issues or anomalies during the battery testing process. This feature provides immediate feedback, aiding in adjusting testing protocols and resolving problems in a timely manner, ensuring the accuracy of test results.

Calibration Function: By using the NEWARE calibration fixture or a multimeter.

Single battery Voltage Acquisition: During the discharge testing process, real-time monitoring of individual battery cell voltages allows for quick and accurate estimation of battery capacity and early detection of excessively high voltage levels. This feature effectively prevents battery damage caused by overcharging or overdischarging.

Infrared Sensing Function: Within a range of 1.5 meters, the infrared sensing feature automatically wakes up the touch screen upon human body detection. Users can conveniently touch and set parameters, making the operation more intuitive.

The sample rack consists of 4 layers, with each layer capable of accommodating 40 button batteries. The all-in-one machine can test 160 button batteries at once. (Battery current I≤100mA)

120°C Fuse Protection: It cuts off the current in case of circuit overload or short circuit to prevent damage to the equipment or wiring. This is an important protective measure in electrical systems to ensure the safety of equipment, circuits, and personnel.

Leakage Protection: The leakage protection system monitors the balance of current entering and exiting. If an imbalance is detected, indicating current leakage through an abnormal path (such as the human body), the leakage protection system swiftly cuts off the circuit to prevent electrical accidents and ensure personal safety.

Short Circuit Protection: Short circuit protection is a safety device used to prevent damage or fires caused by short circuit faults in electrical systems. The short circuit protection device can quickly detect abnormal currents and promptly cut off the circuit to ensure the safe operation of the system and equipment.

Independent Redundant Over-temperature Protection with Circulating Fans: As mentioned earlier, the system has independent redundant over-temperature protection with circulating fans, ensuring a balance between maintaining a constant temperature and cooling.

NEWARE TECHNOLOGY LLC

755 Ames Avenue, Milpitas, CA, USA, 95035